You suddenly find yourself with a malfunctioning heating system in the middle of a cold winter day. This scenario has happened to many of us, and we all know how annoying it can be. So what should you do in this situation? Call a repair service? Of course this is an option, but it could be a costly option!

What if I tell you that you might be able to avoid these costs and fix the heating system yourself? Sounds tough, but the truth is, it is not. Sometimes a malfunctioning heating system is the result of a minor problem that you can easily take care of without calling a professional. Fast and affordable!

For this reason, we have provided solutions for a malfunctioning heating system in this article. You might need to try several solutions to find the one that works and solves the problem. Some of these solutions are simple enough for you to handle on your own, but others require professional assistance or at least some HVAC knowledge.

There are many possible problems that may be causing your heating system to malfunction. This article contains a list of problems and solutions that you can attempt in order to get your heating system working again. As always, working with gas and electricity can be dangerous and we recommend calling a professional to troubleshoot and repair your malfunctioning heating system.

Possible Problems:

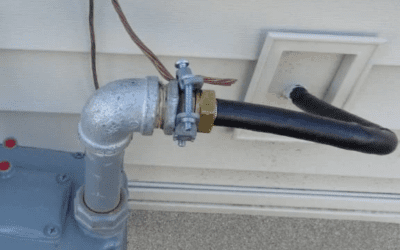

1. The Gas valve

This might sound like a no-brainer, but sometimes, with gas heaters, the problem is as easy as a closed gas valve. Therefore, first you should make sure the gas valve is open. To check this, follow the gas line back to the meter from the furnace to find the valve. Then make sure the handle is parallel to the gas pipe. (see Figure 1)

Figure 1

2. Oil Tank Levels

If you have an oil furnace, check the tank to make sure you actually have enough oil in there. You need at least ⅛ of the tank for the system to operate properly. (see Figure 2)

Figure 2

3. The Thermostat

Frequently, when a homeowner finds themselves with a malfunctioning heating system , it is an issue with the thermostat or how it is set. Programmable thermostats can have many features that make them confusing. Referring to the manual and reviewing the operating instructions may prevent you from paying for a costly or unnecessary service call.

So, take a look at your thermostat. If your thermostat is not working, check the batteries and replace them if necessary. Also make sure the thermostat is set to HEAT and the fan is set to AUTO. (see Figure 3)

Figure 3

4. The Power On/Off Switch

Another reason for a malfunctioning heating system , is the furnace’s power switch. First, make sure that the furnace’s power switch, located on the side of the furnace or on the wall next to the furnace, is in the ON position. (see Figure 4)

Figure 4

If the switch is in the ON position, check the breaker to make sure it did not get tripped.

5. The Furnace Reset Button

The reset button on your furnace is used to reignite the flame that heats the air or water in your system. For every problem related to your furnace, including no heat, no airflow, a noisy furnace, or a smell coming from the furnace, resetting your furnace might solve the problem. The reset button is usually red or yellow and is located in the blower compartment.

Press the reset button once, then listen for a whoosh sound.

Figure 5

If you cannot hear or see the flame after pressing the reset button, DO NOT press the button a second time and start looking for other causes for the malfunction. This is very important as pressing the reset button multiple times can severely damage your system.

6. The Air Vents

If you heat your house with forced air, check that all air vents are open, and no return vents are closed or obstructed. Not only could this solve the problem but it helps the system operate more efficiently.

Figure 6

7. The Air Filter

Every furnace includes a filter that removes dirt from the air before the air is conditioned. One of the main reasons for furnace issues and a source of high operating costs are dirty and clogged filters. (see Figure 7)

Figure 7

A clogged filter might result in two problems. First, the furnace comes on, you can see that the furnace ignites, and the blower fan is working, but it does not heat your home.

Second, the clogged filter causes the limit switch to overheat; shutting off the furnace. How? Well, a limit switch is responsible for monitoring the temperature of the air passing over the heat exchanger. Restriction of the airflow caused by a dirty filter might cause the heat exchanger to overheat, causing the limit switch to shut off the furnace.

For these reasons, you should change your furnace filter every three to six months.

Figure 8

To change the dirty filter, turn off the furnace and look for the filter. It is usually next to the cold air return duct or at the entrance to the blower chamber. So, just slide it out and place the new filter. (see Figure 9)

Figure 9

If changing the filter does not solve the problem, a professional check may be required because there might be another blockage somewhere in the ducts.

Check this out: If there is proper airflow and the blower fan works or cycles on and off, a defective limit switch may cause the issue. This Link shows how you can change your furnace’s limit switch:

8. Radiators

If you have radiators in your home, sometimes you might notice the bottom of the radiator is warmer than the top, it takes longer than usual to heat up, or the radiators become noisy. These are the signs of air getting trapped in the radiator. In this case, you will need to bleed your radiator. To do so, you will need a key that matches the gromit end at the top of your radiator to open the radiator valve and let the air out. However, some modern radiators do not need a radiator key; they just have a small slot in them so that you can use a flathead screwdriver.

Also, you may want to put dust sheets and clothes below the radiator to protect your floors during this process.

First, turn off the heat. Start to turn the key counter-clockwise; it is generally quite tight. After about half a turn, you will hear the air starting to come out. As the air is hissing, hot water is starting to rise up. Sometimes this can take 20, 30 seconds or up to a minute for all the air to come out.

Figure 10

Have your cloth at hand because at any minute water could start coming out.

When the water starts to come out, put your key back in and turn to close it again. Double-check to ensure there is no more water coming out. Then, turn on the heat. Since bleeding radiators can lower your boiler pressure, check to see if the pressure ranges from 1 to 1.5 bars. If the pressure is low, you will need to increase it. Finally, check to see if the radiator is heating up correctly.

9. Furnace Wires

Another problem that can cause the heating system to malfunction is a break in the wire that connects the furnace to the thermostat. Since any damaged wire could be dangerous and cause electrical shock, you should call for professional help to address this issue.

10. Furnace Flame Sensor

The flame sensor’s responsibility is to detect whether a flame is there as soon as your furnace turns on. The sensor will activate safety mechanisms to shut down the device if no flame is found. Otherwise, hazardous gas could leak, accumulate, and cause a fire.

A dirty or defective flame sensor usually results in furnace burners turning on but going out after a few seconds. So, if you have this problem, first, remove the sensor and clean it with a soft abrasive pad. It is a sensitive sensor so any type of dust or carbon buildup could cause it to malfunction.

First, turn off the furnace’s power. If you do not know where to find the flame sensor, remove the furnace’s access panel. The sensor, which looks like a short rod with porcelain around the end connecting it to the burner, is situated right outside the burner assembly. Be careful not to mix it up with the igniter. One wire is usually connected to the flame sensor and two wires to the igniter. (see Figure 11)

Figure 11

Then, disconnect the wire from the flame sensor (see Figure 12).

Figure 12

Next remove the screw that holds the flame sensor in place and pull out the sensor. Be careful to only touch the porcelain part of the flame sensor. (see Figure 13)

Figure 13

Then clean the steel rod with any material suggested in your furnace’s manual. Usually steel wool works well. Remember do not apply a lot of pressure while cleaning.

Figure 14

Finally, reinstall the flame sensor, reconnect the wire, put the access panel back on, and turn on the furnace. If the flame still does not stay on, then try replacing the flame sensor. If the problem still exists, it is time to call a HVAC technician.

11. Furnace Flame Rollout Switch

When burner flames escape from a gas boiler or a furnace’s typical combustion area, this is known as flame rollout. The flame rollout switch is a safety feature used in furnaces to detect a flame rollout. When the temperature outside the combustion chamber rises above a set point, this switch shuts off the gas supply to the furnace.

In Figure 15, you can see a normally operating furnace on the left side versus a furnace with flames rolling out backward on the right side.

Figure 15

There are several reasons the flame rollout switch might trip, such as:

- A dirty burner,

- A blocked flue,

- A cracked heat exchanger,

- A faulty gas valve

- A problem with the electrical igniter.

Moreover, there could be a chance that the flame rollout switch is defective.

When the blower motor and draft inducer both work but the furnace does not turn on, you should check the flame rollout switch to see if it is tripped.

First, turn off the furnace and the gas valve, then remove the access panel. You can find the rollout switch on the side or top of the burner compartment. Most flame rollout switches have a reset button with two wires coming from the back. (see Figure 16)

Figure 16

When the switch trips, the reset button pops out, and by pressing the button you can reset the switch. If you reset the switch, and the switch keeps tripping, then shut your furnace off and call a technician.

If you reset the switch and it starts working, look carefully to see if the flames are rolling out. Also, look for other signs of a flame rollout such as burn marks or discoloration outside the combustion chamber. If you do not see any signs of flame rollout, then the flame rollout switch might be defective and needs to be replaced.

You can replace the flame rollout switch yourself but we highly recommend having an HVAC technician troubleshoot your furnace.

12. Furnace Igniter

Older furnaces commonly use a pilot light to start the heating cycle. In most furnaces today, the pilot light’s open flame has been replaced by a furnace igniter. A furnace igniter is a crucial component of your furnace’s system and one of the most frequent causes of furnace malfunctions. The signs of a defective igniter are:

- The furnace does not come on,

- The furnace goes on and off frequently,

- You feel cold air blowing,

- The breaker trips more than once

- You hear the click when you start the furnace but the air does not blow.

If you see any of these signs, first see if the flame sensor is working properly. If this is not the problem, then you should consider replacing the ignitor.

13. Furnace Draft Inducer

A draft inducer is a fan positioned within your furnace near the heat exchanger that removes combustible gasses. The draft inducer starts 30 to 60 seconds before the start of your furnace’s heating cycle and keeps running throughout each heating cycle.

Tapping and vibrating noises are signs of a bad draft inducer. Since the inducer motor contributes to the safe operation of your furnace, the furnace will typically shut off if the draft inducer does not turn on. So, if your heater shuts off and does not turn on this might be the cause. To address this problem call a technician to check the draft inducer motor or wiring and fix the problem.

14. Furnace Inducer Pressure Switch

A furnace pressure switch is another furnace safety control mechanism, similar to the limit switch. As we mentioned earlier, a limit switch prevents overheating of the heat exchanger. The pressure switch prevents exhaust fumes from entering your home. A pressure switch ensures there is sufficient pressure for the furnace to operate and shuts down the furnace if it senses that the pressure is not enough to force the exhaust fumes outside. The signs of a faulty furnace pressure switch might be airflow with no heat or unusual noises when your furnace attempts to start.

To address this issue, try to identify anything that might cause a change in pressure inside the heat exchanger. The reason might be obstructions in the flue vent, the inducer motor port, a damaged diaphragm, a damaged hose, or maybe water has gotten into the hose.

You will need to do some research if you are a DIY person to fix this problem, but if not, it is time to call a technician.

15. Furnace Blower Motor

The blower motor activates the fan in your HVAC system, allowing air to move through the system and into your home’s rooms.

Figure 17

No or weak airflow, strange sounds, and overheating are the signs of a bad blower motor. To test the blower motor to see if it is working, you need a multimeter. If you do not have a multimeter, you can check a blower motor to determine if it is operating by simply plugging it into a power source (such as a battery). If the blower motor does not turn on or it is broken, you should call a technician to repair or replace the blower motor. But if it works, this is not the cause of your problem.

The Bottom Line

No matter what type of heating system you have, the best thing you can do is keep it well-maintained to prevent the sudden malfunction of the system. If you have older equipment, consider installing a programmable thermostat to ensure it is not running when you do not need it to. This can save on your energy bills too.

You can also opt to replace your system if you find yourself with a malfunctioning heating system. Energy-efficient units are perfect options that cost a bit more upfront, but save you money over time.

Keep in mind that if you are faced with a malfunctioning heating system in the future, consider troubleshooting the system yourself if you are a DIYer. But if you are not comfortable with HVAC work, it might be worthwhile to invest in an emergency repair by a professional.

In the end, it is a good idea to have your heating system inspected by a professional at least once a year. Technicians make sure that your home is safe by inspecting your heating system and ensuring it is working properly and will not cause you any problems in the future.

![Ductless Mini Splits for Philadelphia Row Homes [2025 Guide]](https://matrixgc.com/wp-content/uploads/2025/07/Ductless-Mini-Splits-for-Philadelphia-Row-Homes-400x250.jpg)

Thanks for sharing these helpful tips on troubleshooting a malfunctioning heating system. This information is especially useful during the colder months when we rely on our heating systems to keep us warm and comfortable. The step-by-step approach you provided makes it easy for homeowners to identify and potentially solve common issues with their heating systems. I appreciate the emphasis on safety and the recommendation to seek professional help if needed. Keep up the good work!

Thank you for your kind words and feedback! We’re delighted to hear that you found the troubleshooting tips helpful, especially during the colder months. Ensuring a safe and comfortable heating system is indeed crucial, and we’re glad you appreciate the emphasis on safety and professional assistance when necessary. If you have any more questions or need further assistance, feel free to reach out. We’re here to help! 😊