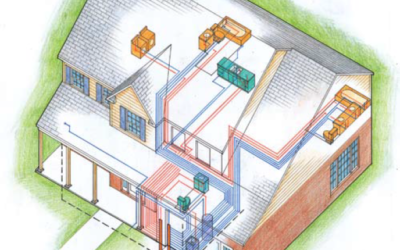

A Pex pipe is a type of plastic plumbing pipe made from cross-linked high-density polyethylene (Pex). These flexible, durable, and easy-to-install pipes have become increasingly popular over traditional copper and PVC pipes for plumbing systems among homeowners and builders. Pex pipes can withstand high temperatures and pressures, making them suitable for a variety of plumbing purposes including hot and cold water distribution, radiant floor heating, and snow-melting systems.

Whether you are planning to install new plumbing in your home or upgrade your existing system, Pex pipes offer a reliable and cost-effective solution that can save you time and money in the long run. In this article, we will explore the types of Pex pipe and Pex fittings as well as provide you with all the information you need to know about this amazing piping material. Let’s get busy!

Types of Pex Pipe

When it comes to categorizing Pex pipe, we can divide them according to their type, color, and size. For anyone who plans to buy Pex pipe, listed below are the most visible features.

Type

Generally, there are three types of Pex pipe:

- Pex-A: Pex-A pipe is the most flexible and durable of the three types. It is made using a high-pressure peroxide method that produces a consistent, cross-linked molecular structure. Pex-A pipe can withstand high temperatures and pressures and is resistant to chemical corrosion. It also has memory properties, meaning it can return to its original shape after being bent. Pex-A is typically the most expensive type of Pex pipe.

- Pex-B: Pex-B pipe is made using a silane method that produces a less consistent, slightly less flexible molecular structure. It is still quite durable and suitable for most plumbing jobs. It is also more affordable than Pex-A and is often used in residential and commercial plumbing systems.

Figure 1

- Pex-C: Pex-C pipe is made using an electron beam method that produces a more irregular molecular structure. It is the least flexible of the three types and has a slightly higher risk of failure. Pex-C is typically used in larger commercial projects.

The table below provides a quick comparison of the three Pex pipes.

| Pex-A | Pex-B | Pex-C | |

| Cross-linked polyethylene | Yes | Yes | Yes |

| Freeze resistance | Yes | Yes | Yes |

| Chlorine resistance | Yes | Yes | Yes |

| ASTM standards | Yes | Yes | Yes |

| Price | High | Low | Low |

| Flexibility | High | Med | Low |

| Kink repair | Yes | No | No |

| Maximum working pressure (psi) | 160 | 160 | 160 |

| Maximum working temperature (F) | 200 | 200 | 200 |

| Cross-linked process | Engel (Peroxide) | Silane (Moisture) | Cold (Electron) |

Table 1

In addition to the above three types, there are also other variations of Pex pipe, such as oxygen barrier Pex, which is used to prevent the diffusion of oxygen into the water supply. This type can be used in radiant heating systems. It is important to consult with a plumbing professional to determine which Pex pipe type is appropriate for your specific job.

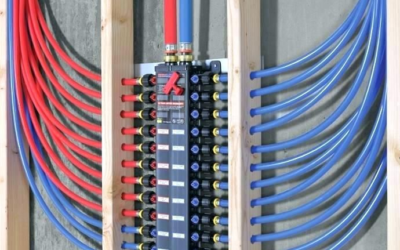

Color

Pex pipes are commonly available in three colors: red, blue, and white. The color of the Pex pipe indicates its intended use and helps in the installation process. Red Pex pipe is typically used for hot water supply lines, while blue Pex pipe is used for cold water supply lines. The white Pex pipe can be used for either hot or cold water supply lines.

While the colors are commonly used to indicate the intended use of the Pex pipe, it is always best to check the manufacturer’s instructions to ensure that you are using the appropriate type of Pex pipe for your specific installation.

Figure 2

Size

Pex pipe is available in ¼ to 1 inch diameters. The most popular sizes are ¾ and ½ inch but you can also find them in 1 inch as well as smaller sizes such as ⅜ and ¼ inch. The small sizes are typically used for small-scale plumbing projects.

Pex Fittings

Pex fittings are used to connect different Pex pipes together and also to connect Pex to other types of pipes such as copper, providing a secure, leak-free connection. They are available in different sizes and are commonly made of brass, plastic, or stainless steel. The type of fitting used will depend on the specific use and Pex pipe type. There are various types of Pex fittings available, including:

- Coupling: A coupling fitting is used to join two Pex pipes together in a straight line.

Figure 3

- Elbow: An elbow fitting is used to change the direction of the Pex pipe. It is available in different angles such as 45 degrees or 90 degrees.

Figure 4

- Tee: A tee fitting is used to create a T-shaped intersection where three Pex pipes can be connected.

Figure 5

- Reducer: A reducer fitting is used to connect pipes of different sizes. One end is larger than the other, allowing for a transition between two different pipe sizes.

Figure 6

- Valve: A valve is used to control the flow of water through the Pex pipe system. There are different types of valves such as ball valves, gate valves, and angle valves.

Figure 7: Pex Female Brass valve

- Adapter: An adapter fitting is used to connect Pex pipes to other types of pipes, such as copper or PVC.

Figure 8

- Cap: A cap fitting is used to seal the end of a Pex pipe.

Figure 9

- Cross: A cross fitting is used to connect four Pex pipes.

Figure 10

How to Connect Pex Fittings

The Pex fittings discussed above can be connected using different methods. The method used depends on several factors including the Pex type used. The following explains the most common connection methods used for Pex fittings.

1. Crimping

Crimping is one of the most popular and cost-effective methods for connecting Pex fittings. A crimp ring made of copper or stainless steel slides over the Pex tubing, and then a crimping tool with an interchangeable head for specific size fittings is used to compress the ring tightly around the tubing and fitting, creating a leak-proof seal. This method can be used with Pex-A, Pex-B, and Pex-C.

Figure 11

Figure 12

2. Clamping

Clamping is another popular and affordable method for securing Pex fittings. A stainless steel clamp ring is placed over the Pex tubing and the fitting, and then a clamp tool is used to tighten the clamp ring around the tubing and fitting. One of the benefits of this method is that you can use the clamp tool for every ring and fitting size. This method can be used with Pex-A, Pex-B, and Pex-C.

Figure 13

Figure 14

3. Compression

Compression fittings use a threaded nut, a compression ring (ferrule), and a fitting body to create a leak-proof connection. The Pex tubing is inserted into the fitting, and the nut is tightened to compress the ring onto the tubing, creating a seal. This method does not require a tool. This method can be used with Pex-A, Pex-B, and Pex-C.

Figure 15

4. Push-fit

Push-fit or push-to-connect fittings are designed for quick and easy installation without any tools. The Pex tubing is simply inserted into the fitting, which has a locking mechanism that holds the tubing securely in place. Sharkbite fittings are a type of push-fit fitting that uses a unique design to grip the Pex tubing securely. The fitting has a stainless steel grip ring that holds the tubing in place and a specially designed O-ring that creates a watertight seal.

If your work simply requires a few connections or you are doing a small repair, the SharkBite will likely be the fitting system of choice because it is easy to use and requires no equipment; nevertheless, the fittings are more expensive per piece than the other systems. This method can be used with Pex-A, Pex-B, and Pex-C.

Figure 16

5. Expansion

For the expansion method, you need an expansion fitting, expansion ring, and expansion tool to stretch the Pex tubing, allowing the fitting to be inserted into the Pex tubing. The tubing then shrinks back to its original size, creating a tight seal around the fitting. This method is commonly used in commercial plumbing jobs and can be used only with Pex-A.

Figure 17

Figure 18

6. Press

Press fittings use a press tool to create a permanent connection between the Pex tubing and fitting. The fitting has a stainless steel sleeve that is inserted over the Pex tubing, and a press tool is used to compress the sleeve tightly around the tubing and fitting, creating a secure and leak-proof seal. It is worth noting that you should choose the press tool corresponding with the size of your Pex pipe and fitting. This method can be used with Pex-A, Pex-B, and Pex-C.

Figure 19

Figure 20

Which Pex Pipe is Best for Your House?

Choosing the Pex pipe type for your house will depend on various factors, such as the specific needs of your plumbing system, budget, and personal preference. Here are a few things you should consider when choosing the Pex pipe type for your house:

- Local building codes and regulations: Check your local building codes and make sure you are permitted to use Pex piping in your area. It is important to ensure that the pipe you choose complies with local building codes and regulations. According to the Plumbing Code 2018 of Philadelphia (adopted with amendment International Plumbing Code 2018 (IPC 2018) you are allowed to use Pex in Philadelphia.

- Purpose: Different Pex pipe types are better suited for different purposes. For example, Pex-A may be more suitable for hot water lines, while Pex-B is a common choice for general plumbing lines.

- Cost: Pex-A is typically the most expensive Pex pipe type, while Pex-B and Pex-C are more affordable options. Consider your budget and weigh the cost against the benefits of each type.

- Warranty: Different Pex pipe manufacturers may offer different warranties for their products. Consider the warranty offered for each Pex pipe type and factor that into your decision.

- Professional Consultation: A professional plumber can help assess your plumbing needs and recommend the best Pex pipe type for your house. They can also ensure that the installation complies with local building codes.

In general, Pex-A and Pex-B are commonly used in residential plumbing systems due to their flexibility, durability, and ease of installation. Pex-C is less flexible but has excellent chlorine resistance, making it suitable for areas with high levels of chlorine in the water.

Pex-B is the most common type of Pex pipe used in Philadelphia residential plumbing systems due to its affordability and reliability, which makes it a popular choice among homeowners and plumbing professionals.

Which Connection Method Should You Use?

Choosing the correct connection method for your Pex pipes is important. Although it is not a tough decision, you should compare the pros and cons of each connection method in order to decide which one best suits your needs. The Table below compares the different connection methods from various aspects to help you choose the right one.

| Connection Method | Required Tools | Pex Pipe Compatibility | Price | Pros | Cons | ||

| A | B | C | |||||

| Crimping | Crimping tool | Yes | Yes | Yes | Low | Fast and easy to install,

Inexpensive, Suitable for high-pressure applications,

|

Requires professional tools,

Requires tool calibration |

| Clamping | Clamping tool | Yes | Yes | Yes | Low | Fast and easy to install,

Inexpensive, Suitable for high-pressure applications, Suitable for hard-to-reach locations |

Requires professional tools,

Requires tool calibration Not suitable for hot water systems |

| Compression | No tools | Yes | Yes | Yes | Med | Quick and easy to install,

No tools required, Suitable for both hot and cold water systems |

Suitable only for small-diameter Pex pipes,

|

| Push-fit | No tools | Yes | Yes | Yes | High | Fast and easy to install,

No tools required,

|

Less reliable especially for high-pressure applications,

Expensive, Susceptible to freezing and pulling |

| Expansion | Expansion tool | Yes | No | No | High | Quick and easy to install,

Suitable for larger tubing diameters and hot water systems, approved to be buried directly in soil and concrete |

Requires professional expensive tools |

| Press | Press tool | Yes | Yes | Yes | High | Quick and easy to install,

reliable |

Requires professional tools,

Requires a separate tool for each Pex size, Expensive |

Table 2

Conclusion

We hope you found this article informative and helpful in understanding the features of Pex pipes for plumbing systems. Since Pex pipe is becoming widely used, it is essential to learn about the different types, the fittings, and the connection systems available. By choosing the appropriate Pex pipe, fitting, and connection system for your installation, and following the manufacturer’s instructions as well as the local building codes, you will have a safe and reliable plumbing system. However, consulting with a licensed plumber or contractor is always recommended when it comes to plumbing systems.

If you are in need of professional assistance with any Philadelphia area home renovation, feel free to contact Matrix Company Solutions Corp. for a free consultation. We will be more than happy to help!

![A Comprehensive Guide to the Hierarchy of Using Building Codes in Philadelphia [2025]](https://matrixgc.com/wp-content/uploads/2025/04/Using-Building-Codes-in-Philadelphia-blog-article-1080x675.jpg)

0 Comments