Have you ever noticed the yellow tubing behind your stove that connects it to the gas line? If your home’s gas line is not old, you will likely find all your movable gas appliances, including your stove and dryer, are connected to the gas piping system using that yellow tubing. That tubing is a Flexible Appliance Connector (FAC) commonly known as a gas connector.

The first time people see CSST (Corrugated Stainless Steel Tubing), they might think it is just tubing connecting their stove to the gas line. But that’s not the case! Many people confuse CSST with FAC. While both are yellow gas piping, they function differently; confusing them can be dangerous!

We wrote different articles about CSST and decided it was a good idea to write about the differences between CSST and FAC to ensure nobody confuses them. This article will provide valuable insights if you are curious about these gas tubings and their differences. Keep reading!

What are the Functions of CSST and FAC Pipes?

Let’s begin by explaining what CSST and FAC do. “CSST” stands for Corrugated Stainless Steel Tubing, a common material in gas piping systems since 1990. Instead of traditional iron pipes, CSST is used to carry gas from the meter throughout a building. Its main job is gas distribution.

Now, let’s talk about Flexible Appliance Connectors or FACs. These flexible hoses or tubings link gas appliances to the gas supply line. In simpler terms, FAC connects your building’s gas distribution system to your appliances.

Figure 1

Why Do People Mix Up CSST and FAC Pipes?

It’s easy to understand the confusion! CSST and FAC serve a similar purpose; they transport gas from one point to another. Both are flexible and made from stainless steel. They even have similar names. In the industry, Flexible Appliance Connectors are called Corrugated Stainless Steel connectors (CSSC). Plus, typically, they both come in the same color – yellow! Despite having distinctive features, a quick look might make them seem alike, causing confusion.

Understanding the specifics of these materials and their differences is the key to this problem. Many people lack the information in this article, making it easy to confuse CSST and FAC. Read on to learn the differences and never mix them up again!

Differences

Now, let’s get to the key distinctions between CSST and FAC across various aspects.

1. Appearance

Both CSST and FAC are corrugated pipes. However, CSST has a yellow or black sheathing over the corrugation. FAC does not have sheathing, is painted yellow, and the corrugation is visible.

2. Material

CSST is primarily corrugated stainless steel and has a plastic outer sheath. Traditionally made of corrugated brass, FAC is now made of corrugated stainless steel.

3. Purpose

The most significant difference between these two is the purpose of using them. CSST transfers gas from the meter to the building, but we use gas connectors to connect appliances to the piping system. While you can directly connect CSST to fixed appliances, it should not substitute for a gas connector. You can connect CSST directly to fixed appliances but not movable appliances, while gas connectors can connect to both.

4. Installation

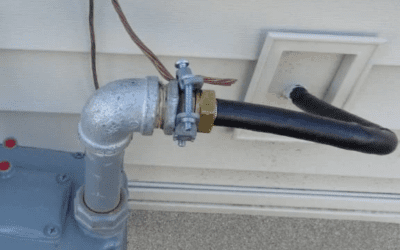

Installing CSST involves running the tubing through walls, floors, and ceilings and connecting it with compatible fittings (see Figure 2). It’s important to note that only certified CSST installers can perform this installation.

Conversely, FAC has fittings at both ends, making the installation easier. You can effortlessly connect the flexible connector to the gas supply line and the appliance (see Figure 3).

Read more: How to Install a CSST Flexible Gas Line

Figure 2: CSST Fittings

Figure 3: FAC with integrated fittings

5. Size

CSST is usually larger (¾” and 1″ +) than FAC (⅜” and ½”). FACs are between 1 and 6 feet long, while CSST comes in rolls as long as a few hundred feet. You can easily cut them to the required length.

Figure 4: CSST roll

6. Cost

CSST has a higher initial cost due to material expenses and professional installation, but Flexible Appliance Connectors have a lower initial cost, especially for DIY installation.

7. Lifespan

CSST provides long-term value with durability and flexibility for future appliance changes (up to 30 years). FAC may require more frequent replacements due to a shorter lifespan (approximately 10 years) and wear.

For a quick comparison between CSST and FAC, check out the table below:

Table 1: CSST and FAC Comparison

| CSST | FAC | |

| Appearance | Corrugated pipes with a sheathing (yellow or black) | Corrugated pipes without sheathing, colored in yellow |

| Material | Stainless steel with an outer plastic sheath | Traditionally brass, Stainless steel |

| Purpose | Gas distribution throughout the building | Connects appliances to the piping system |

| Appliance connection | Allowed only for fixed appliance | Allowed for both fixed and movable appliances (Occasional movement is allowed) |

| Installation | More complicated, certified installers required | Simple installation |

| Size | Larger (¾” and 1”+) | Smaller (⅜” and ½”) |

| Cost | high | low |

| Lifespan | Up to 30 years | Approximately 10 years |

How to Distinguish between a CSST and a FAC?

CSST and a gas appliance connector can look very similar. However, one feature sets them apart. CSST has a flexible outer yellow polyethylene sheath (although some brands use black). On the other hand, gas connectors are also yellow, but this color serves as a coating on the tubing itself.

In Figure 5, you can see an example of gas connectors and CSST. Although they are made of the same stainless steel material, you can distinguish them by their outside coatings. The CSST has a thin jacket, which allows you to see the ridges of the stainless steel. The gas connector has a much thicker coating with an accordion rubber-like look.

Figure 5

Considerations for Flexible Appliance Connectors

- Some old brass gas connectors (from the 1970s) are dangerous and prone to leaking. Replace them ASAP. The new gas connectors, meeting the ANSI Z21.24 standard, are made from stainless steel.

- Ensure there’s a shut-off valve at or very near the FAC.

- Avoid connecting two or more FACs.

- Don’t bend the connector too sharply or stretch it too much. Bends with a radius smaller than 1 ½ inches and right-angle bends are not allowed.

- Use each FAC for one appliance only.

- Check if the connector is approved for high-pressure gas if needed (> ½ psi).

- Don’t use gas connectors for appliances that move often (like LP tanks). Most FACs are designed for occasional movement.

- Replace connectors whenever replacing an appliance. The gas connectors are designed for one-time use only.

- It would be best never to hide gas connectors inside walls, floors, etc. (see Figure 6).

Figure 6

Conclusion

Congratulations! You have reached the finish line and can now distinguish CSST from FAC pipes. Just remember, as CSST grows in popularity, replacing old iron pipes might be tempting. But when it comes to gas, safety comes first. Gas piping is no DIY adventure; leave that to the pros. Call a qualified gas fitter if anything about your gas pipes seems unclear. With their expertise, you can rest assured your home’s gas system runs smoothly and safely. So, stay informed, stay safe, and enjoy the peace of mind of knowing your gas is in good hands!

![Philadelphia Sump Pump Installation Requirements [2025 Guide]](https://matrixgc.com/wp-content/uploads/2025/06/Philadelphia-Sump-Pump-Installation-Requirements-2025-Guide.png)

![A Comprehensive Guide to the Hierarchy of Using Building Codes in Philadelphia [2025]](https://matrixgc.com/wp-content/uploads/2025/04/Using-Building-Codes-in-Philadelphia-blog-article-400x250.jpg)

0 Comments