Whether you’re framing a rowhouse addition or upgrading a historic storefront, understanding the hierarchy of using building codes ensures your project meets every legal, safety, and performance requirement. In Philadelphia, that means navigating layers from broad federal laws down to the fine print in manufacturer manuals. This guide walks you through each tier, showing which rules prevail when they conflict. Let’s get started!

What Are Construction Codes and Standards?

Before diving into the specifics, let’s break down what construction codes and standards really are. Essentially, these are sets of rules, guidelines, and technical specifications designed to ensure that buildings are safe, functional, and energy efficient. They cover everything from structural integrity and fire safety to accessibility and environmental impacts. Think of them as the building blocks that keep our built environment reliable and secure. The hierarchy of using building codes in Philadelphia is structured to make sure that every detail, from the simplest fixture to the most complex structural element, is considered.

Codes vs. Standards vs. Testing Labs: What’s the Difference?

1. Codes

Codes are laws. They’re adopted by a government body- federal, state, or local- and carry the force of law. If you break a building code, you can be fined, have your permit revoked, or be forced to rip out work that doesn’t comply.

2. Standards

Standards are technical documents created by industry organizations (ANSI, ASTM, NFPA, ASHRAE, etc.) that describe “best practices” or performance criteria. Standards become enforceable only when a code (or contract) references them by name.

The standards often become part of the building codes by reference. These include:

- ANSI (American National Standards Institute)

- ASTM International

- ASCE (American Society of Civil Engineers)

- NFPA (National Fire Protection Association)

- ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers)

- ACI (American Concrete Institute)

- AISC (American Institute of Steel Construction)

These standards support the hierarchy of using building codes by ensuring that every component, from structural elements to fire safety systems, is designed and installed according to proven, reliable practices.

3. Testing Labs & Certifications

Once we know that codes are the laws we must follow and standards are the detailed methods they reference, the next piece of the puzzle is proving that products and assemblies actually meet those standards. That’s where testing labs and certifications come in.

Testing laboratories perform the hands‑on work of putting a product, whether it’s a fire‑rated door, an electrical panel, or a structural connector, through the exact tests specified by a standard. Once a lab verifies that the product passes, it issues a certification mark.

Now, what are Nationally Recognized Testing Laboratories, or NRTLs? These labs have met strict requirements themselves, like using calibrated equipment, following written quality procedures, and holding regular audits, so you can trust their results. Only an NRTL certification can satisfy certain code mandates for safety‑critical items.

One of the most familiar NRTLs is Underwriters Laboratories (UL). When you see the little “UL” mark on a light fixture or circuit breaker, it means UL has tested that product against specific safety standards and certified that it meets or exceeds them. Inspectors in Philadelphia and across Pennsylvania look for that UL mark as clear evidence that the device complies with the National Electrical Code and other relevant requirements.

In short, Codes tell you what minimum you must do, while Standards tell you how to do it correctly, and Testing Labs then prove that a product satisfies those standards (and thus the code’s requirements).

Why a Hierarchy Matters

Understanding and following the hierarchy is essential when working with building codes. Imagine trying to build a house without knowing which rules to follow first. Do you check the federal regulations or the local zoning code? What if the manufacturer’s installation manual contradicts the city’s requirements? The hierarchy tells you exactly which document “wins” when two sets of rules conflict. By following it, you:

- Stay legal, avoiding fines or stop‑work orders

- Keep people safe by respecting proven safety measures

- Save time and money by preventing rework or permit delays

Authorities Having Jurisdiction (AHJs)

In the US, the rules that govern how we design, build, and renovate structures come from a series of overlapping authorities called “Authorities Having Jurisdiction,” or AHJs.

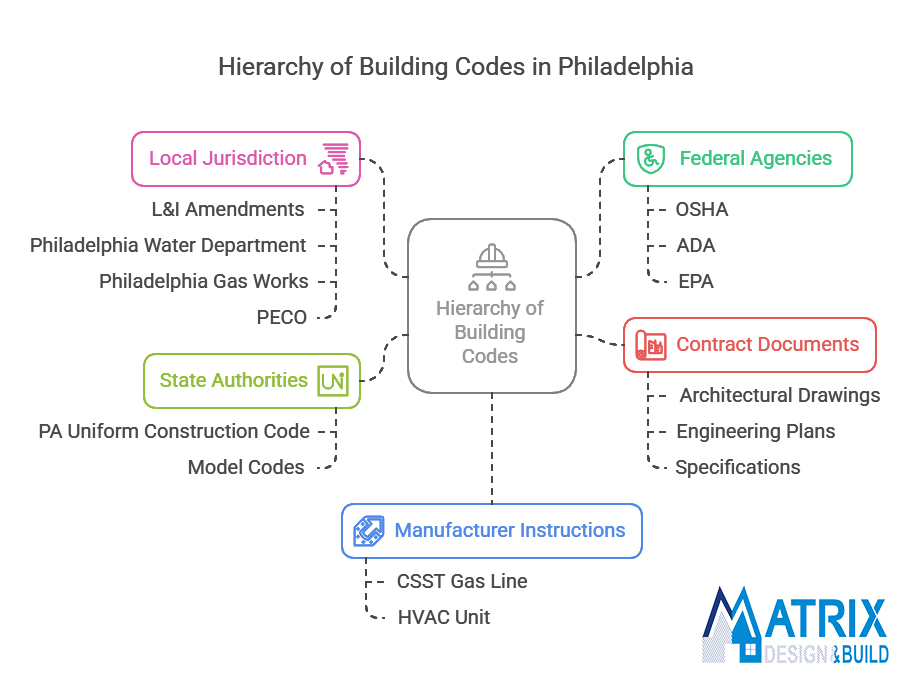

1. Federal Agencies

At the very top, federal agencies such as OSHA (Occupational Safety and Health Administration), ADA (Americans with Disabilities Act), and EPA (Environmental Protection Agency) that apply everywhere in the United States. Those national mandates tell us, for example, how to protect workers on site, manage stormwater runoff, or ensure that public buildings accommodate people with disabilities.

2. State Authorities

The Commonwealth of Pennsylvania’s Uniform Construction Code (UCC) is directly beneath those federal requirements. The UCC incorporates a family of model codes, most notably the International Building Code (IBC), the International Residential Code (IRC), the National Electrical Code (NEC), and the International Plumbing Code (IPC), and then adjusts them to reflect state priorities. Through the Department of Labor & Industry, Pennsylvania certifies third‑party agencies to verify compliance, so that every corner of the state follows a consistent baseline.

Model codes are like ready‑made rulebooks written by industry experts. Instead of every city writing its own laws, they adopt these templates, such as the ICC’s International Building Code, NFPA’s fire and electrical codes, or IAPMO’s plumbing and mechanical codes, and then make local tweaks. Once a model code is officially adopted by a state or city, it carries the force of law in that jurisdiction.

3. Local Jurisdiction

In Philadelphia, the Department of Licenses & Inspections (L&I) serves as the primary Authority Having Jurisdiction (AHJ) for all building work. Under Subcode B, L&I has adopted the 2018 International Building Code (IBC), along with its companion residential, mechanical, plumbing, energy, and fire I‑Codes, and then layered on a series of city‑specific amendments. Those local refinements cover everything from historic‑district protections and heightened energy‑efficiency requirements to sidewalk and curb standards, zoning setbacks, and other urban‑unique concerns.

Starting in July 2025, Philadelphia will transition to the 2021 I‑Codes, with all new permit applications required to comply by 2026. In every case, when you submit plans for review, L&I compares them not only against Pennsylvania’s Uniform Construction Code but also against Philadelphia’s own amendments, always enforcing whichever rule is more stringent.

Beyond L&I, several other local bodies maintain parallel regulations that can affect your project.

- Philadelphia Water Department (PWD): Manages stormwater, sewer connections, and water supply.

- Philadelphia Gas Works (PGW): Oversees gas line installations and ensures compliance with the relevant gas codes.

- PECO (Electric Utility): Regulates electrical service connections, meter installations, and ensures adherence to NEC‑based standards.

They may impose extra requirements to ensure that their systems remain safe and reliable. These policies sit alongside building codes, adding another layer to the hierarchy of using building codes. Always follow the most stringent requirement when faced with conflicting information.

4. Manufacturer Installation Instructions

These are detailed guidelines provided by product manufacturers. While they’re critical for ensuring that equipment (like a CSST gas line or HVAC unit) is installed correctly, they must always be followed in a way that does not conflict with higher-level codes.

5. Contract and Construction Documents

Every construction project in Philadelphia culminates in a detailed set of contract documents, architectural drawings, and engineering plans that reference this vast hierarchy. Here’s how they fit into the overall picture:

- Architectural & Engineering Drawings:

These documents must adhere to all applicable codes, standards, and manufacturer instructions. They translate the theory of codes into practical, on-site applications. - Specifications:

Often intertwined with contractual documents, specifications will reference various standards (ASTM, ANSI, etc.) to ensure that materials and methods meet the highest safety and quality benchmarks. - Contractor’s Means & Methods:

Even though contractors might have their own preferred methods of doing work, their practices must fully comply with the established hierarchy. No matter how innovative a method may be, it cannot bypass critical safety standards.

Special Considerations

Not every project is straightforward. Special circumstances may necessitate additional considerations:

- Historic Districts:

Work on historic buildings typically requires extra approvals and adherence to additional guidelines from the Philadelphia Historical Commission. - Flood Zones:

Projects in flood-prone areas must align with FEMA guidelines and local stormwater rules from the Philadelphia Water Department. - High-Rise Buildings & Special Occupancies:

These projects often fall under stricter fire, structural, and egress requirements. - Tenant Fit-Outs:

Renovations that convert or upgrade existing spaces must respect both the original building codes and any new requirements stemming from updated occupancy or use standards.

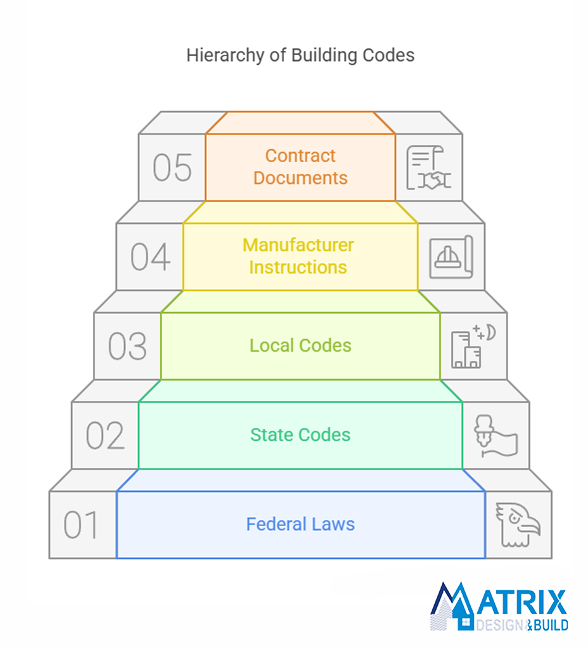

Summing It All Up: The Hierarchy of Using Building Codes in Philadelphia

In summary, the hierarchy of using building codes can be visualized like this:

- Federal Laws (OSHA, ADA, EPA, and more) form the top, establishing the most general, yet compulsory, requirements.

- Pennsylvania State Codes (such as the PA Uniform Construction Code and L&I regulations) refine these rules further.

- Philadelphia-Specific Codes & Local Amendments adjust state-level guidelines to address local nuances.

- Manufacturer Instructions offer detailed steps for installing particular products, always secondary to established codes.

- Construction Contract Documents and Approved Plans bring everything together into practical, legally binding directions.

Final Thoughts

Understanding the hierarchy of using building codes is crucial for anyone involved in construction or renovation in Philadelphia. By appreciating each level, from federal laws and state codes down to manufacturer manuals, you can ensure that your project complies with all necessary regulations, avoids costly mistakes, and ultimately results in a safe, durable, and efficient building.

Remember, when different documents conflict, always follow the most stringent requirement. When in doubt, consult a qualified professional to help navigate these layers. By respecting each part of the hierarchy, you not only adhere to the law but also contribute to a safer, more resilient built environment.

If you have any questions, let us know in the comments below.

References:

- https://forum.nachi.org/t/international-residential-code-irc-vs-local-codes/115417/4

- https://www.construction-physics.com/p/how-building-codes-work-in-the-us

- https://www.phila.gov/departments/department-of-licenses-and-inspections/resources/applicable-codes

- https://www.phila.gov/departments/department-of-licenses-and-inspections

![Top 20 Reasons for Failing a Plumbing Inspection in Philadelphia [2025 Guide]](https://matrixgc.com/wp-content/uploads/2025/05/Common-issues-causing-failing-a-plumbing-inspection-in-Philadelphia.png)

0 Comments